Sustainable Development

Practicing Sustainable Construction

Ruentex initially focused on serving its business group, but over time, it expanded its operations by undertaking external projects and introducing new technologies. Through continuous efforts in professional engineering, Ruentex has secured a firm position in the construction industry. As one of the industry leaders, we not only strive to deliver the highest product quality to our clients but also place equal importance on addressing today’s pressing environmental issues.

Ruentex actively promotes a variety of sustainability initiatives, including the application of precast technology, low-carbon construction methods, the integration of green electricity and renewable energy into production processes, and waste reduction. We are committed to being a “practitioner of sustainable construction.”

In response to the global net-zero movement, Taiwan’s National Development Council announced the 2050 Net-Zero Emissions Pathway in March of last year. The Ministry of the Interior is responsible for promoting net-zero buildings, with the goal that by 2050, 100% of new buildings and over 85% of existing buildings will achieve near-zero carbon emissions. For the construction industry, one of the key approaches to supporting this policy is the adoption of low-carbon construction techniques.

Ruentex has been deeply engaged in the development of precast construction technology for many years and is now the largest precast plant in Taiwan. Precasting is a modular construction method that revolutionizes traditional processes by allowing multiple tasks to be carried out simultaneously. This significantly reduces labor requirements and construction time, thus shortening project timelines and cutting costs.

For example, the reinforced concrete (RC) precast method moves most of the on-site construction tasks to the factory, including the production of major structural elements such as beams, columns, and slabs. On-site work is minimized to assembling components, rebar connections, and a limited amount of concrete pouring. In factory settings, the use of machinery and lifting equipment allows multiple operations to occur at once, greatly reducing manpower and time. Due to these characteristics, the precast method significantly reduces the energy consumption and carbon emissions associated with material production and construction.

Ruentex will continue to enhance both the depth and breadth of its precast applications, aspiring to become a transformative force in the construction ecosystem and a true practitioner of sustainable construction.

Currently, approximately 40–45% of Ruentex’s ongoing projects are in high-tech factories, about 20% are residential construction projects, and 10–15% are public infrastructure. After more than 20 years of continuous development in precast construction, we are now seeing broader applications across various project types. We firmly believe that these efforts will generate positive impacts on our environment and society, contributing meaningfully to sustainable development and the achievement of net-zero goals.

High-Tech Factory Construction

Ruentex’s precast construction method has been extensively applied in the construction of high-tech factory and office buildings, leading the industry with outstanding performance—including achieving the milestone of completing a factory in just 100 days. This allows Ruentex to provide clients with fast and high-quality services, enabling earlier factory operations that enhance product competitiveness. Additionally, by shortening the construction schedule, carbon emissions generated during the construction process are significantly reduced. The tangible benefits include:

- Minimized on-site concrete formwork, reducing formwork usage by 90% and construction waste accordingly.

- Minimal on-site supports, with support area reduced by 80%, improving site logistics and safety management.

- Precast and modular construction shortens project duration by approximately 27%.

- Reduced labor demand, cutting on-site workforce needs by two-thirds, helping to alleviate labor shortages in the construction industry.

- Over 120 precast-related patents acquired across six countries.

Wanhua Anju Social Housing

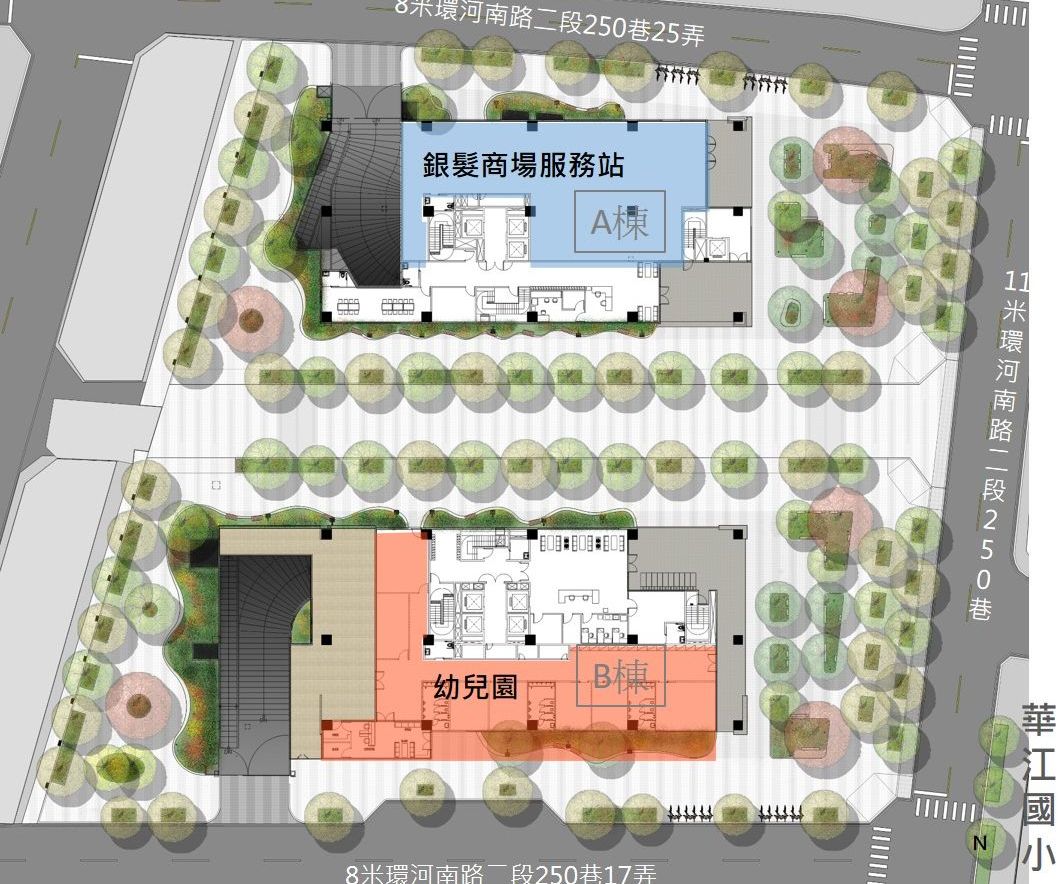

The “Wanhua Anju” social housing project consists of two sites located in Huajiang Village, Wanhua District, Taipei City. The buildings are 13 stories above ground with 2 basement levels, providing a total of 300 social housing units. Constructed by Ruentex, the project began in 2021 and is scheduled for completion in 2024.

Commissioned by the National Housing and Urban Regeneration Center, Wanhua Anju is the first project in Taiwan to adopt a hybrid construction method combining precast components with aluminum formwork. The use of precast exterior wall panels eliminates the need for external scaffolding, offering a safer and faster alternative to traditional methods. The smooth surfaces of the precast panels reduce the need for plastering and finishing, which in turn cuts down on materials and on-site labor requirements. This approach not only saves energy and reduces carbon emissions but also helps address labor shortages in the construction industry.

In addition to its ideal location and convenient transportation, the Wanhua Anju project incorporates community welfare facilities to serve local residents, creating a win-win scenario. The housing offers a stable living environment for low-income groups and young working professionals, helping to ease social and economic pressures.

Dormitory Building for Medical Staff of Taipei Veterans General Hospital

Medical Staff Dormitory Building – Taipei Veterans General Hospital

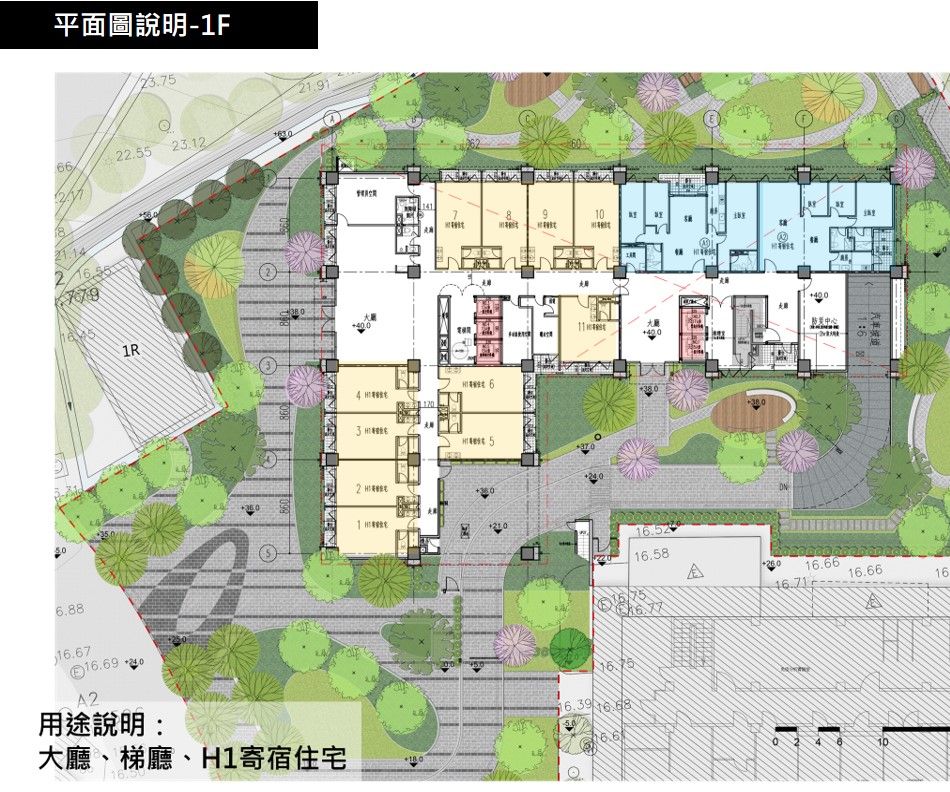

The Medical Staff Dormitory Building at Taipei Veterans General Hospital is a new construction located on the former site of the Chang-Ching Building. The project consists of an 18-story above-ground structure with 1 basement level. Funded by a donation from Ruentex Innovation and constructed by Ruentex Engineering, the project broke ground in 2023 and is scheduled for completion in two phases between the second half of 2024 and 2025.

This building serves as a demonstration project for Ruentex’s next-generation precast construction method. The design is based on a high-percentage precast strategy: structural columns, beams, exterior walls, and balconies of the above-ground levels are all fabricated at the precast plant and then transported to the site for floor-by-floor installation. The precast components are integrated with in-situ cast concrete floor slabs to ensure both comfort and seismic resilience.

Notably, the exposed surfaces of the precast components are pre-tiled at the plant, eliminating the need for scaffolding and on-site tile workers. This significantly reduces on-site labor—by approximately two-thirds compared to conventional methods—and minimizes the environmental and safety impacts on the surrounding area.

The use of precast technology combined with 3D modeling to integrate the structural and MEP (mechanical, electrical, and plumbing) systems has effectively shortened the construction timeline and improved build quality. This streamlined approach ensures timely delivery of modern, high-quality housing for hospital staff.

To further enhance living conditions, sound-insulating flooring is used to reduce noise transmission between floors, ensuring undisturbed rest for off-duty staff. These design choices contribute to a more supportive work environment, ultimately promoting the well-being of medical personnel and enabling them to deliver better healthcare services.